horizontal balancing machines Horizontal Balancing Machines: The Key to Efficient Rotor Balancing

horizontal balancing machines Horizontal Balancing Machines: The Key to Efficient Rotor BalancingHorizontal balancing machines are essential tools designed for the dynamic balancing of various rotating components, including turbines, fans, shafts, and centrifugal machines. These sophisticated devices help in eliminating unbalance in rotors, enhancing their performance, extending their service life, and ensuring operational safety.

Understanding Horizontal Balancing Machines

At their core, horizontal balancing machines are designed to accurately measure and correct unbalance in rotating bodies. This process ensures that the mass of rotors is distributed evenly around their axes of rotation, significantly reducing vibrations during operation. Effective balancing of rotors leads to improved functionality, reduced wear and tear, and minimal energy losses.

Types of Horizontal Balancing Machines

There are two primary types of horizontal balancing machines: soft bearing machines and hard bearing machines. Each type has unique features that cater to specific balancing needs and applications.

Soft Bearing Machines

Soft bearing machines utilize flexible support systems to accommodate unbalance forces. These machines are designed with suspensions or spring-mount systems that allow for low natural frequencies compared to the operational frequencies of the rotors. This flexibility enables them to balance rotors at various speeds, starting as low as 200 RPM.

A classic example of soft bearing balancing machines includes setups where components are mounted on spring-supported frameworks. Such designs are attractive to many manufacturers and hobbyists due to their simpler construction and lower manufacturing costs.

Hard Bearing Machines

On the other hand, hard bearing machines utilize rigid supports with complex cut-outs to manage unbalance during operations. These machines offer higher versatility and precision when balancing rotors across a broader range of sizes and weights. They are particularly effective for balancing at lower rotational speeds, allowing for intricate balancing of more massive components.

The construction of hard bearing machines supports ensures that they can withstand higher operational loads, making them suitable for demanding applications in various industries.

Features and Advantages of Horizontal Balancing Machines

Investing in horizontal balancing machines offers numerous advantages that contribute to operational efficiency:

- Enhanced Performance: Properly balanced rotors operate more smoothly, leading to increased efficiency and reduced energy consumption.

- Increased Longevity: By minimizing vibrations, these machines help extend the service life of rotating equipment and minimize maintenance costs.

- Safety: Reducing imbalance decreases the risk of mechanical failures which can lead to hazards in the workplace.

- Cost-Effectiveness: With the ability to create DIY balancing machines, companies can significantly cut down on equipment costs while still meeting balancing needs.

Selecting the right horizontal balancing machine depends on several factors, including:

- Type of Application: Consider the size, weight, and operational speeds of the rotors that need balancing.

- Precision Requirements: Identify the balancing tolerances necessary for specific applications to choose between soft and hard bearing machines.

- Available Resources: Assess whether you want a fully manufactured solution or prefer designing and building a custom machine to suit your specific needs.

For those interested in constructing their own horizontal balancing machines, there are extensive resources available. Many enthusiasts and engineers opt to build DIY machines to achieve significant cost reductions. The key to successful DIY balancing machines lies in understanding the required components, such as:

- Support Structure: A robust bedframe with appropriate bearings is essential for both soft and hard bearing machine designs.

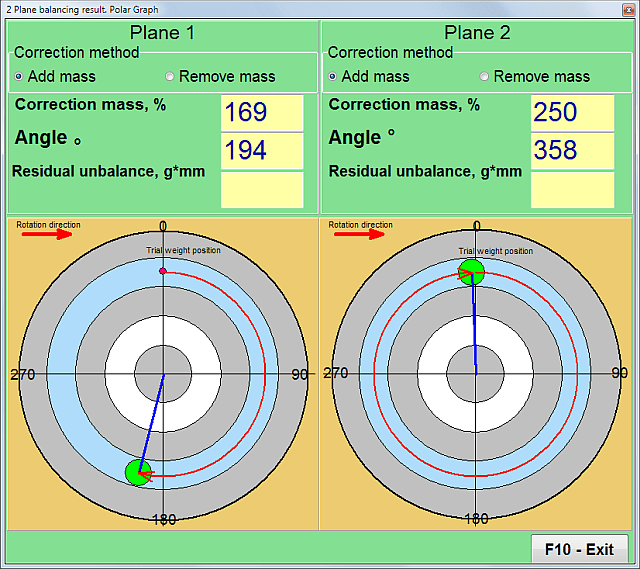

- Measurement Systems: Utilizing vibration sensors and phase angle sensors can provide precise measurements needed to determine unbalances.

- Drives: The driving mechanism must be capable of providing the necessary rotation speeds to achieve effective balancing.

Horizontal balancing machines are vital for any operation involving rotating equipment. Whether considering commercial balancing services or exploring DIY options, understanding the types and functionalities of these machines can lead to improved operational efficiency and safety. By investing in or creating the right horizontal balancing machine, businesses and manufacturers can achieve optimal performance from their rotating devices, thus ensuring longevity and reliability.

Explore Our Range of Balancing Machines

Check out our selection of portable balancers and vibration analyzers, like the Balanset series, to find the perfect solution for your balancing needs. Whether for personal use or industrial applications, we provide the tools necessary for effective rotor balancing.

https://mylesetgu14792.wizzardsblog....alanset-device https://jeffreyxwsm93827.qowap.com/8...alanset-device http://veraciousrp.listbb.ru/viewtopic.php?f=87&t=940